1000W 1500W 2000W Handle Laser Welding Cleaning Cutting Machine Relfar System Three

Overview Package Size 110.00cm * 80.00cm * 150.00cm Package Gross Weight 150.000kg Product Description The hand-held fib

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | TXT-HJ-SC1500 |

| Technical Class | Continuous Wave Laser |

| Control | Manual |

| Power Density | Deep Fusion Welding |

| Laser Classification | Optical Fiber Laser |

| Type | Optical Fiber Transmission Laser Welding Machine |

| Laser Power | 1000W / 1500W /2000W /3000W |

| Cooling Method | Integrated Water Cooling |

| Power Stability | +_2% |

| Laser Power Adjus Range | 10% - 100% |

| Function | Welding / Cutting / Cleaning |

| Condition | New |

| Speed | up to 7000mm/S |

| Power Supply | AC 110V/220V 50Hz |

| Welding Gun | Handheld + Wobble Head |

| Welding Line | No More Than 0.2mm |

| Laser Source | Fiber Laser |

| Wire Feeder Kit | Included |

| Fiber Length | 10m |

| Welding Speed | up to 120mm/S |

| Laser Wavelength | 1064nm |

| Transport Package | Plywood Case |

| Specification | 960*550*750mm |

| Trademark | TXT LASER |

| Origin | China |

| HS Code | 8515809090 |

| Production Capacity | 100sets/ Month |

Packaging & Delivery

Package Size 110.00cm * 80.00cm * 150.00cm Package Gross Weight 150.000kgProduct Description

Product DescriptionThe hand-held fiber laser welding machine (3 in 1) changes the traditional welding method, using a high-intensity laser beam as the heat source for welding, and is equipped with a hand-held welding head to replace the previous fixed optical path. It has the advantages of simple operation, beautiful welding seam, fast welding speed and less consumables. Widely used in aviation, aerospace, sporting goods, jewelry, golf head, medical equipment, aluminum denture, instrumentation, electronics, machining, automotive and other industries, especially for gold and silver jewelry fill the hole, point weld lines, mosaic pieces and claw foot unit area. In addition, after we change the lens and the corresponding copper nozzle, then switch to the cleaning and cutting mode through the control system of the equipment.

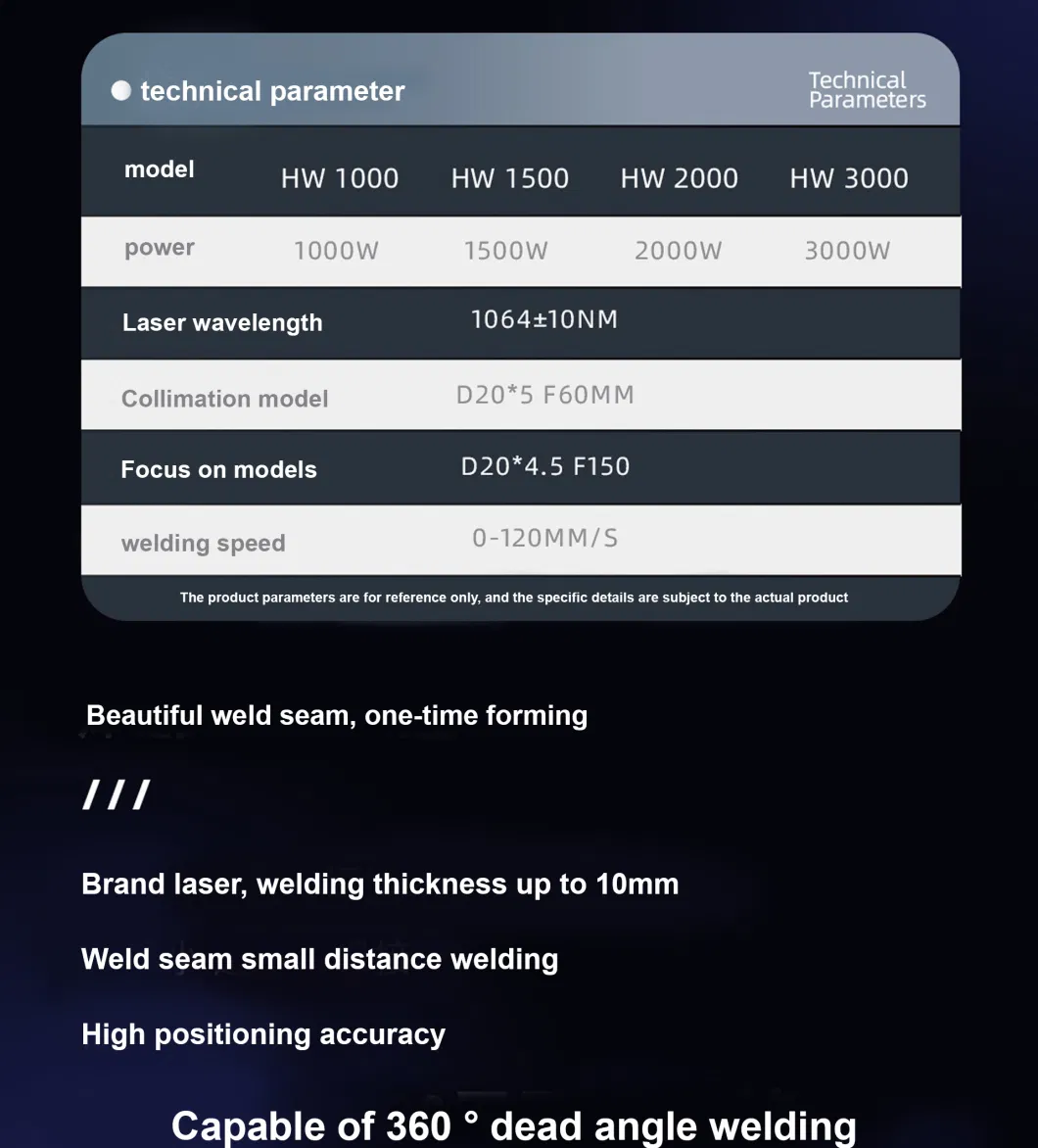

Product Parameters| Model | TSC-1000 | TSC-1500 | TSC-2000 |

| Power | 1000w | 1500w | 2000w |

| Wavelength | 1064nm | ||

| Laser Source | Fiber Laser (CW) | ||

| Laser Power Adjus Range | 10% - 100% | ||

| Power Stability | ±2% | ||

| Cooling Method | Integrated water cooling | ||

| Fiber Length | 10m / 20m / Cutomized | ||

| Power Supply | AC 110V/220v 50Hz | ||

| Welding Gun | Handheld + Wobble Head | ||

| Wire Feeder Kit | Included | ||

| Max Welding Depth | 2mm | 2.5mm | 3mm |

| Welding Line | ≤0.2mm | ||

| Welding Speed | ≤120mm/s | ||

Our Advantages

Wuhan Tianxingtong Optoelectronic Technology Co., Ltd. is a technology enterprise committed to the research and development, production and sales of laser equipment and automation equipment. The company is located in Xinte Optoelectronic Industrial Park, Jiangxia District, Wuhan City. Tianxingtong photoelectric team has more than 20 years of laser industry experience, 18 R & D personnel, equipment annual shipments of 1000+, to provide customers with: free proofing, 8 hours on-site service, 24 hours to help customers solve after-sales problems.As an industry and trade integrated enterprise, TXT laser adheres to quality as the center, service as the core, and constantly carries out core technology innovation and research and development, and is committed to providing better laser cutting solutions for global customersProduct serialization, diversification, to meet the needs of more customers, excellent product quality and durability, to create maximum value for customers, timely after-sales service, professional and efficient problem solving, free sample cutting, free customer training, mass exhibition support, support OEM,ODM cooperation.

Packaging & ShippingFAQQ1. How to select the suitable machine?

Tell us your material, detail requirements by words, pictures or video.

We will recommend you the suitable model with the reasonable price.

Q2. How about the lead time?

For the standard machine, the delivery time is 7-15 working days after the payment.

For the non-standard machine, the delivery time is 15-20 days after the payment.

Q3. How to install and use it?

We have the instruction Book, Operational manual and Training Video inside the machine.

We also can provide the training on line by free.

Q4. How to do it if we meet the issue during the operation?

You can send the wrong information to us by mail, we can help us solve it by mail.

phone, or video communication.

Q5. If we want to learn how to operate the machine, Can you provide it?

Yes, we can. We can provide the on line training by video. We also provide free training

course in our company.

Q6. Do you provide the onsite service if we needed?

Yes. We can provide the onsite service if you needed. But need the customer pay for the transport, hotel, food and 60USD/day.