Automatic Control System of The Expansion Machine Apply in Feed Industry

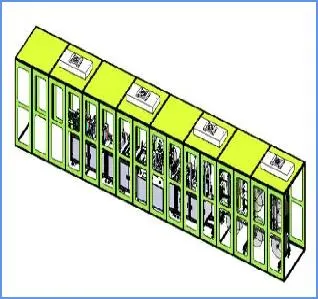

Overview Product Description 1. the expansion machine feeder can use the weight scale feed (optional), can accurately co

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | SWD |

| Pellet Mill Type | No |

| Bulking Machine Type | Twin Screw Bulking Machine |

| Expanding Method | Wet Expansion |

| Condition | New |

| Applicable Materials Shape | Granular |

| Warranty | as Per Contract |

| Material | Seamless Pipe and Carbon Steel |

| Weight | 620kg |

| Water Demand | 1500kg Per Hour |

| Air Demand | 1000kg Per Hour |

| Voltage | 380V 50Hz |

| Output | 5~10ton Per Hour |

| Power | 3kw |

| Model | Swd-2 |

| Transport Package | Wrap and Pallete |

| Specification | 2000*2000*3500mm |

| Trademark | LEADING |

| Origin | Yangzhou |

| HS Code | 8423309090 |

| Production Capacity | 500/Sets |

Product Description

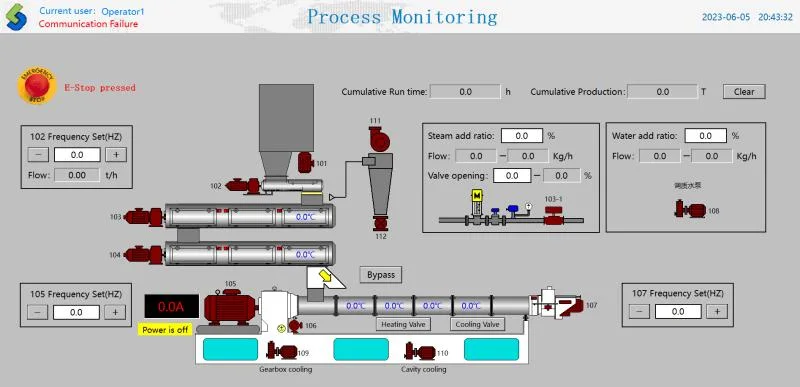

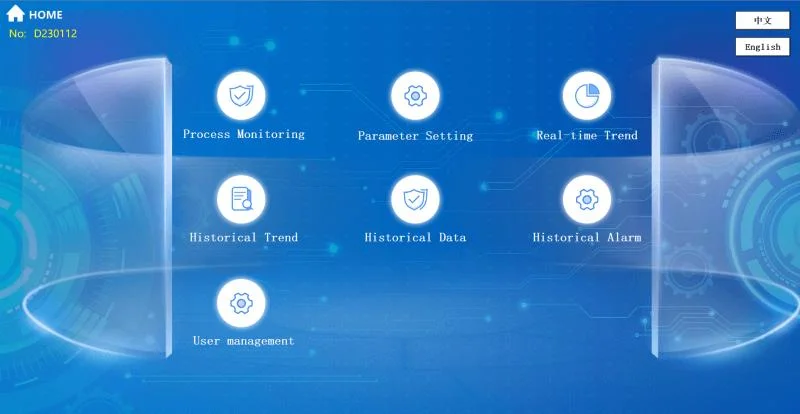

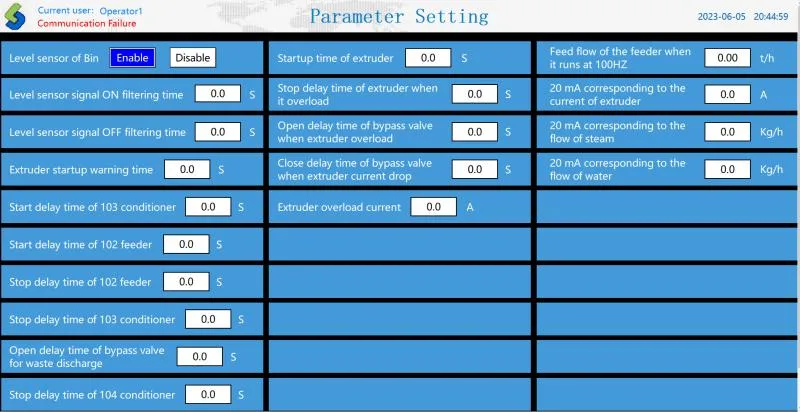

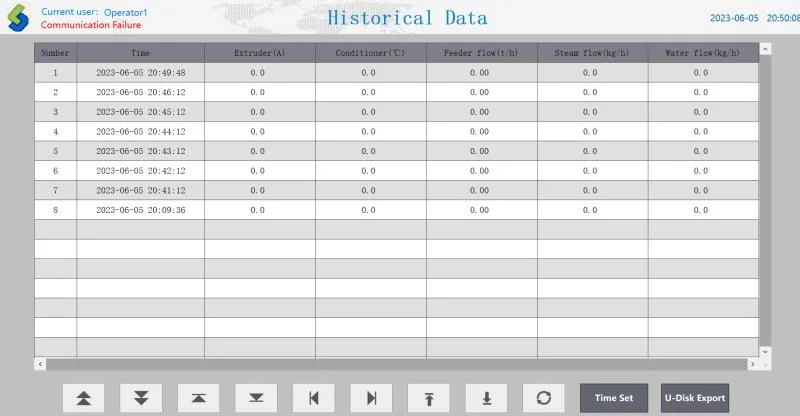

Product Description1. the expansion machine feeder can use the weight scale feed (optional), can accurately control and calculate the instantaneous flow and accumulation of materials, the weight scale measurement accuracy of 1%. 2. Adjust the instantaneous flow of steam and water through the proportional valve control to ensure the best adjustment temperature; 3. The expansion machine host load control (frequency converter selection), to ensure that the equipment works in the best load, the equipment operation overcurrent protection. Low-current no-load prompt. 4. The equipment has two working modes: manual and automatic, and the equipment is in chain operation state; a variety of fault sound and optical alarm, fault information database history record and can be searched and traced; 5. Equipment operation three-level authority management; 6. Steam consumption collection (optional items), energy consumption management. 7. All data historical trend records are queried and traceable. And can be data-exported or uploaded. 8. Support for Modbus TCP or Modbus RTU protocol remote monitoring and data linking. 9. Support for Internet, WiFi remote maintenance function

Detailed Photos

Certifications

Packaging & Shipping Company Profile

Leading is a high-tech enterprise in Jiangsu Province, the two factories cover a total area of 25 mu, the registered capital of 20 million, with more than 30 doctor, master, bachelor, college and other high and intermediate professional and technical talents.Mr.Wu Bing, the founder of the company, and his core team have started businesses in the feed industry for more than 30 years. The main computer factory automation control and management system, batching system, microscale, measuring equipment, robot palletizing packaging line.The earliest batching system and full-screen computer control system in China were developed by the core team of the company, among which the batching system won the third prize of scientific and technological progress of the Commerce Department; the electrical control system project of the turnkey delivery feed plant.In 2014, the company focused on the layout of China's biological fermentation industry, dedicated on the research of equipment and production process, and provided customers with the design, development, manufacturing, installation of a complete set of fermentation production line turnkey project.The company has 2 software product certificates, 6 software copyright certificates, 12 utility model patent certificates, 1 appearance design patent, 1 manufacturing measuring instrument license certificate.The company cooperates with domestic well-known biotechnology companies to provide customers with a full set of solutions from biotechnology, process to equipment manufacturing, complete production line "handover key" project.The company has provided different customers with fermentation equipment, production line process and solutions for special materials for many times.The company has provided different customers with fermentation equipment, production line process and solutions for special materials for many times.

FAQ

1. Can you supply OEM or ODM?Answer: Yes, we do. We can manufacture the machines according to your exact requirements.2. What is your delivery time?Answer: Generally the delivery time is 7 - 15 days after down payment receiving. But the exact delivery time will depend on your quantity and your ordering time.3. Will you dispatch engineers to our factory for installation or training?Answer: Yes, we can arrange our engineers to customers' factories for installation and training, and we will calculate all the cost to customers. If you have your own engineers team, we can supply you manual book and guide video, keep 24 hours online to cooperate your engineers to finish the installation and operation.4. Can you also supply me related machines together?Answer: Yes, we can. We can supply not only a complete production line, but also the upstream and downstream machines, such as grinding machines, packing machines etc. If you purchase other goods, you can also send your other goods to our factory for loading together.5. What is the payment terms?Answer: We accept 30% T/T as deposit and the balance by T/T before shipping. We can also accept L/C, D/A, D/P, T/T, Western Union, MoneyGram etc. based on different orders.6. Can you guarantee your quality?We purchase quality spare parts and raw materials which are produced by famous brand manufacturers, so that we can assure the quality of machines we supply to customers are high and reliable.